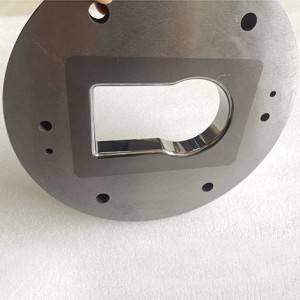

Tungsten carbide stamping dies & mould

Tungsten Carbide Stamping Dies & Mould

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Material grade list

|

Chinese Grade |

Equal to ISO Category Number |

chemical composition |

Physical mechanical properties |

Application |

||||

|

WC |

Co |

Density |

Bend Strength |

Hardness |

||||

|

% |

% |

g/Cm3 |

N/mm2 |

HRA |

||||

|

YG3 |

K01 |

96.5-97 |

3 |

14.9-15.3 |

≥1180 |

≥91.0 |

It is suitable for the finishing of cast iron, non-ferrous metals, alloys and non-metallic materials, and semi-finishing vehicles for intermittent cutting. | |

|

YG6X |

K10 |

93.5 |

6 |

14.8-15.1 |

≥1420 |

≥92 |

Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron | |

|

YG6 |

K20 |

94 |

6 |

14.7-15.1 |

≥1600 |

≥91 |

Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

|

YG8 |

K20-K30 |

92 |

8 |

14.5-14.9 |

≥1600 |

≥90 |

Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials. | |

|

YG10 |

K40 |

90 |

10 |

14.3-14.7 |

≥1900 |

≥89 |

It is used for large batch production and has excellent strength and toughness. | |

|

YG10X |

K40 |

89 |

10 |

14.3-14.7 |

≥2200 |

≥89.5 |

Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

|

YG15 |

K30 |

85 |

15 |

13.9-14.2 |

≥2100 |

≥87 |

Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses | |

|

YG20 |

K30 |

80 |

20 |

13.4-13.7 |

≥2500 |

≥85.5 |

Stamping die, stamping watch parts, musical instrument spring piece; | |

|

YG20C |

K40 |

80 |

20 |

13.4-13.7 |

≥2200 |

≥82 |

Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die, warhead to the shell of the stamping die | |

|

YG30 |

70 |

30 |

12.75 |

≥2500 |

≥82.8 |

High toughness | ||

PRODUCTION DISPLAY

![[Copy] MP Plantary concrete mixer](http://cdn.globalso.com/blockbrickmachine/93d21737-300x300.jpg)